During my first year of University 2019, I worked with my university professors and the TVS Motor Company on a pilot project where a team (consisting of my friends and I) built a computer vision AI system to spot defects in bike parts during manufacturing. The system used TensorFlow and deep learning to detect issues like tank cap alignment, air bubbles, lamp sticker presence, and more — all by analyzing images from a single camera on the assembly line.

We trained the model using real factory data, manually labeling images to help the system learn what to look for. Despite a tight schedule and ongoing college work, we managed to keep everything on track. It was a great experience combining hands-on AI with real-world impact, and I learned a lot about deploying machine learning in industrial settings.

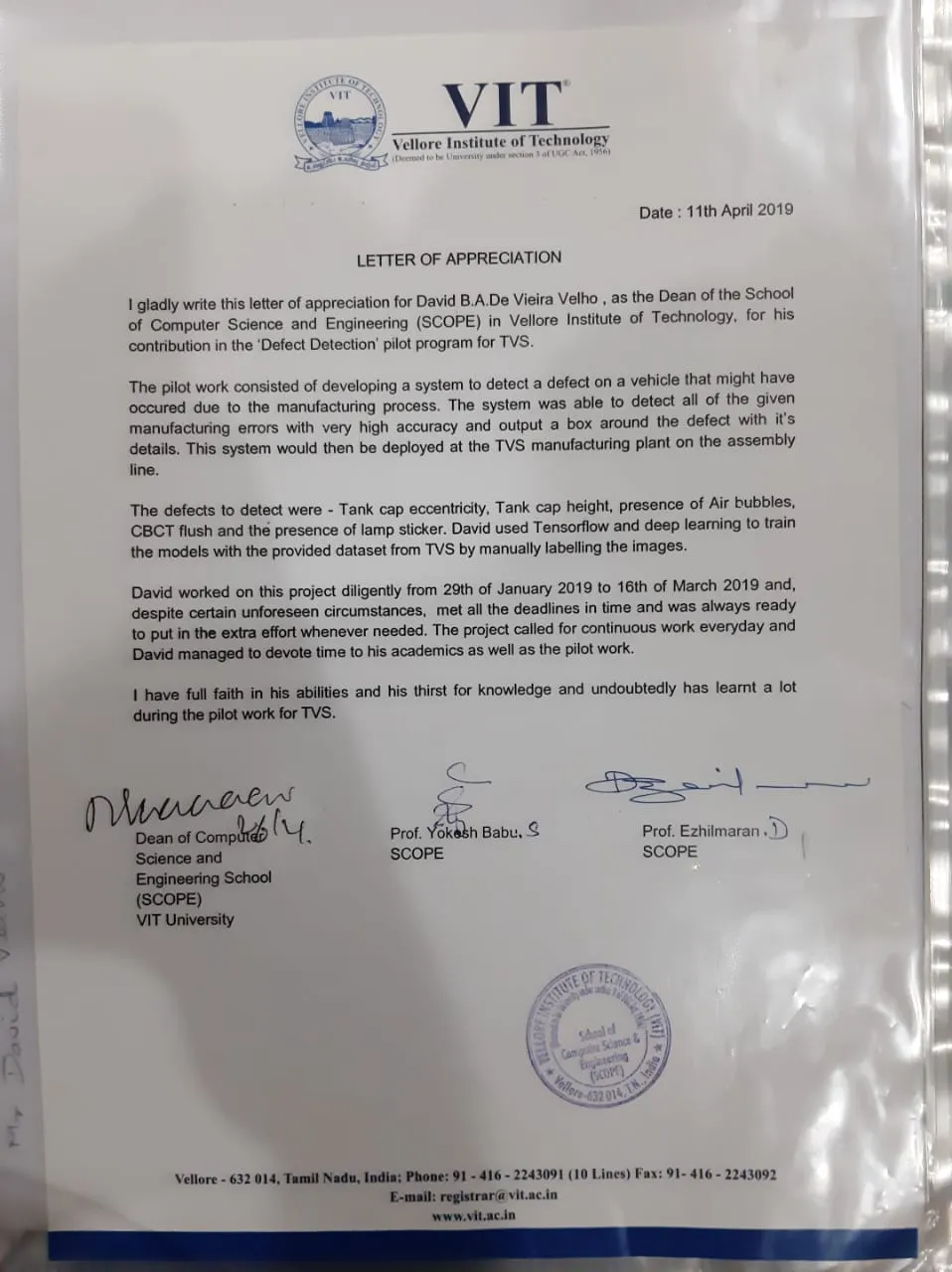

We were later awarded a letter of appreciation for our efforts and a bump in GPA for that semester